digital powerplant

A nuclear energy plant’s innovation team brought us on board to conduct ethnographic research to assess the feasibility and projected value of procedure automation software.

TL;DR: I had coffee with an old professor and 2 weeks later, he bought me a pair of steel-toes boots and I found myself in the depth of a nuclear reactor. It was super cool.

︎︎︎

In-Depth Ethnographic Research

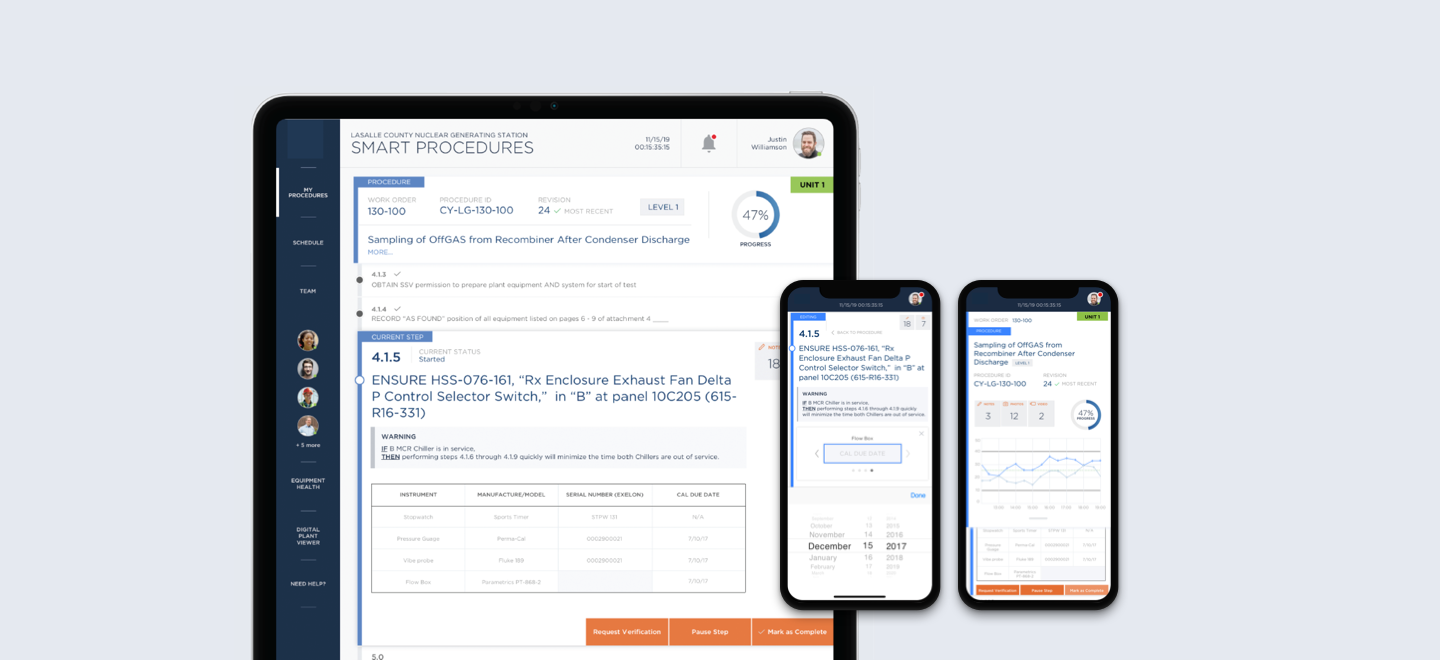

RESEARCH400,000 procedures x 100 pages avg. = 40 million static pdf pages

“Okay, so let’s make an app.”

This is one of my favorite stories, especially for selling the design value proposition. What happens when a management consulting firm implements a very one-dimensional digitization strategy by converting printed paper PDF’s into static PDF’s on iPads and Apple Pencils to annotate? You get:

- almost-retired engine operators holding what’s functionally the same thing as printed paper but heavier,

- approximately $20 million in conversion and technology costs, and

- a longer work process — operators were printing the converted PDF’s, completing the procedure manually, scanning it back in, and then submitting it to records.

OBJECTIVES

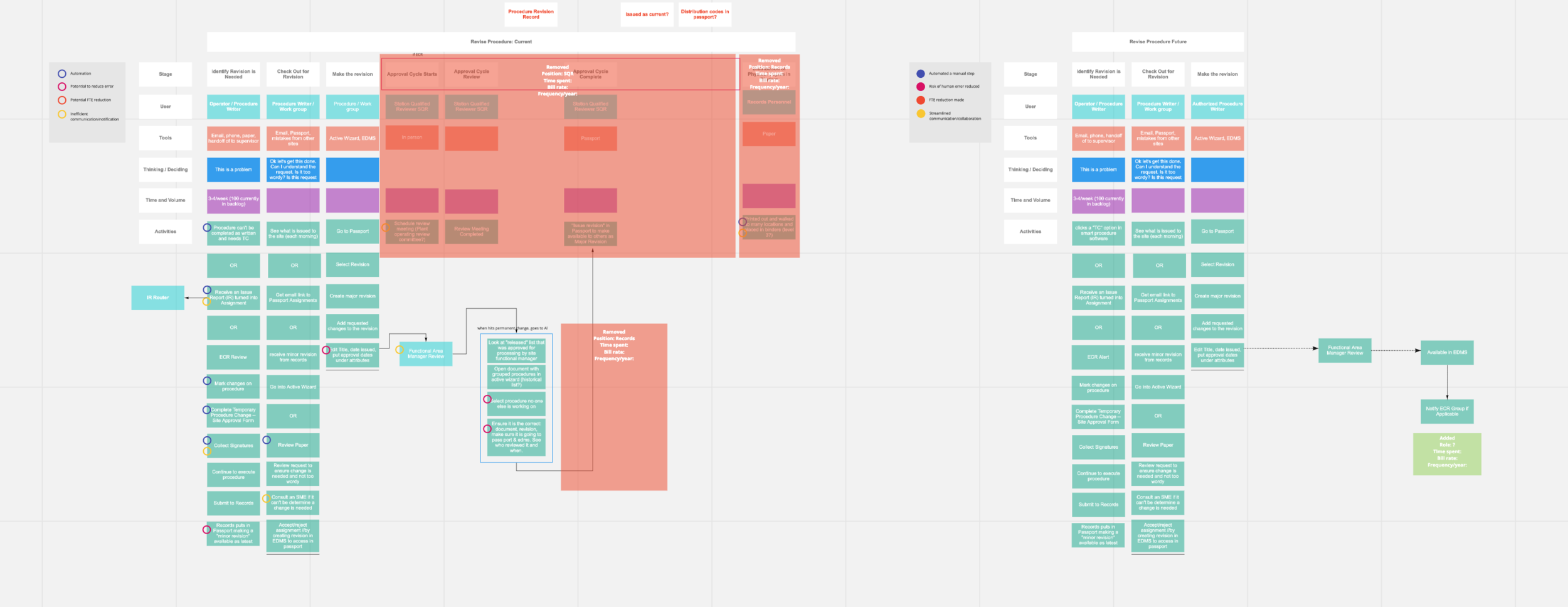

- Document current state of the procedure lifecycle

- Document business benefits and use cases

- Identify platform requirements

- Evaluate potential third-party software solution

- Ideate a digital future-state to leverage automation

INTERVIEWEES

- Engine Operator

- St. Coordinator

- St. Clerk

- Procedure writers

- OP CAT

- Scheduling

- Work Management

METHODS

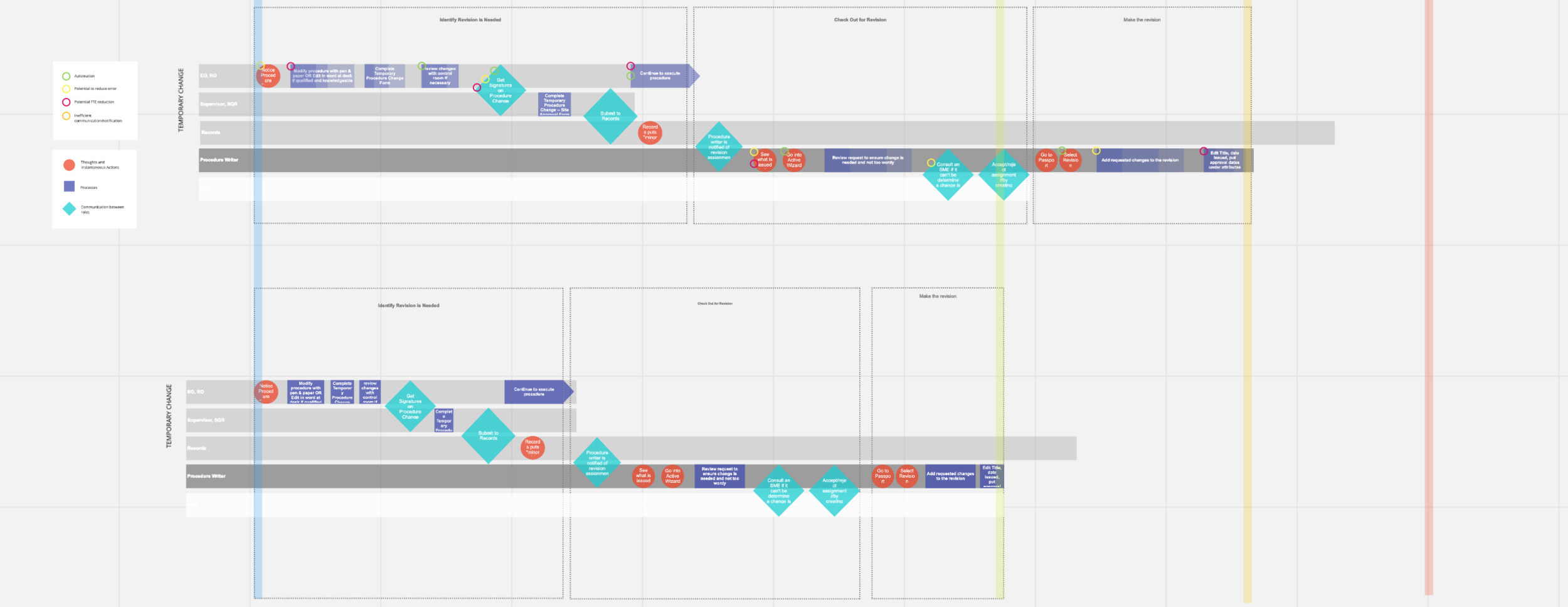

- Observe 3 procedures in conversion process

- Shadow 2 procedures fully executed

- Observe and record side-by-side manual vs. mock automated

executions

- Listen to and transcribe team brief in the control room

Project Value Analysis

BUSINESS CASE

“Procedures can take anywhere between an hour to 2 weeks.

“I submit paper copies…not really at a certain time. Just whenever it builds up.”

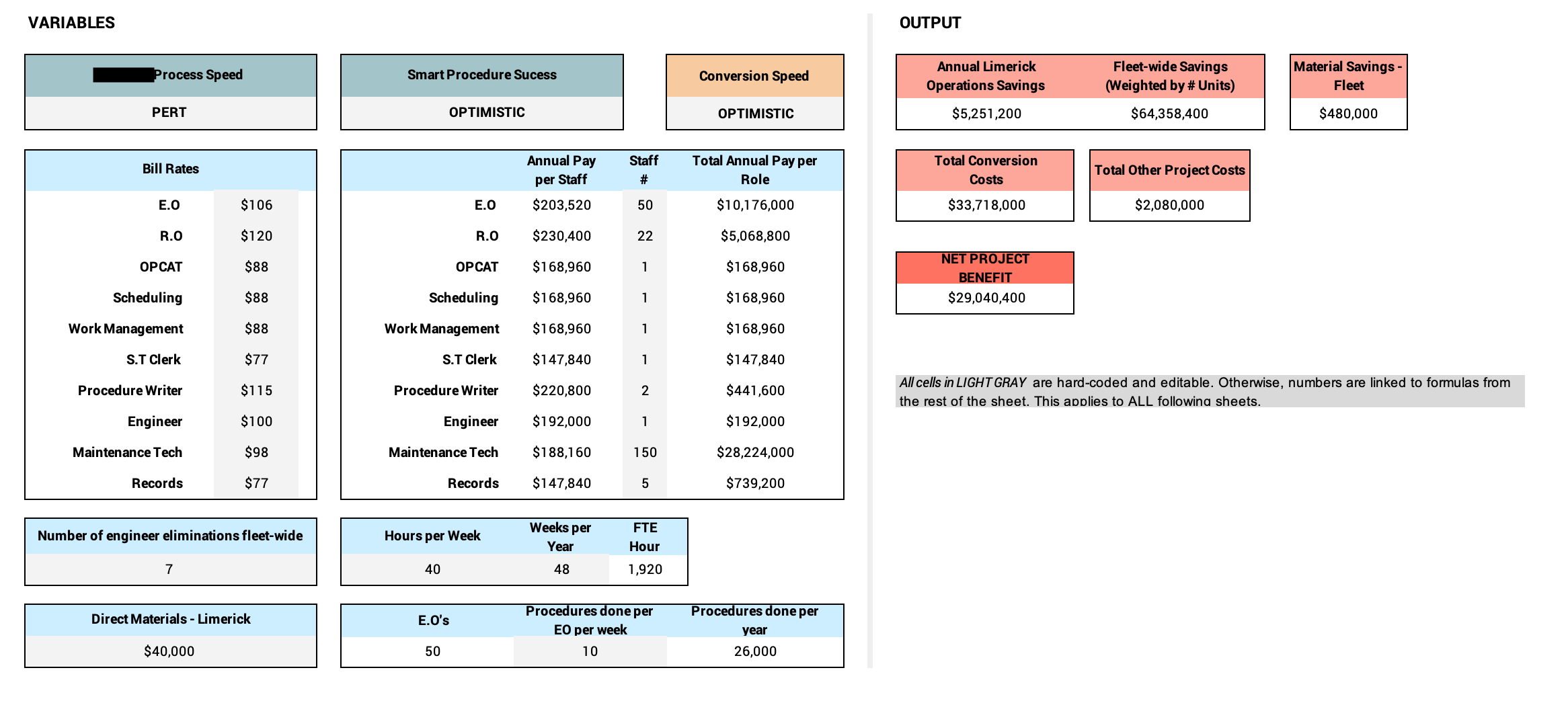

...giving clients an extrapolated report would create a certain level of doubt. However, presenting the entire pack of raw data and formulas would be dizzying and overwhelming.

The solution was to put power into the clients’ hands: A locked-down, stylized, and usable spreadsheet that functioned as a calculator with customizable inputs.

INPUTS: Direct labor information (bill rates, staff volume, FTE hours, etc.); workload volumes ( # procedures per week, etc.); conversion information (avg # pages per procedure, minutes needed per page, etc.)

OUTPUTS: Savings (labor, materials); costs (material, project); deployment timeline; net project benefit

Innovation team lead:

“You must have a certain level of OCD to make something like this, right?”

—

CEO of Daito Design: